MTi BLASTBAG™ Case Study – Flyrock Reduction in Surface Blasting

Site Profile

The Challenge

A gold mine in West Africa producing more than 85,000 ounces annually struggled with excessive ejections and dangerous flyrock during blasting.

Homes and public infrastructure were close to the boundary, making flyrock a serious safety risk. Despite efforts to fix the issue with new blast designs and blast mats, ejections continued. After a tragic incident, the mine suspended drilling and blasting near the boundary until a safer method could be found.

That’s when MTi Group was asked to help.

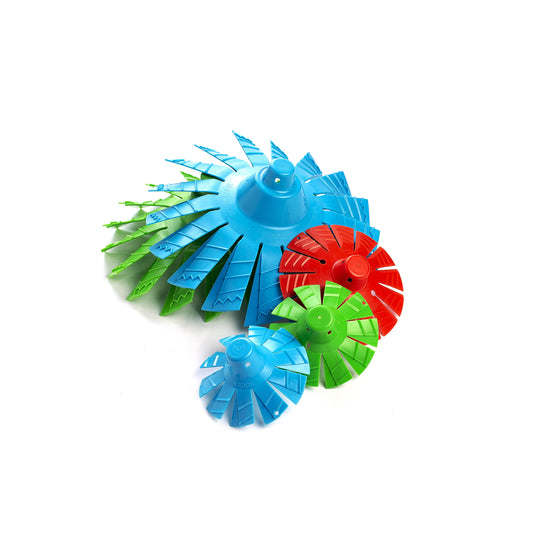

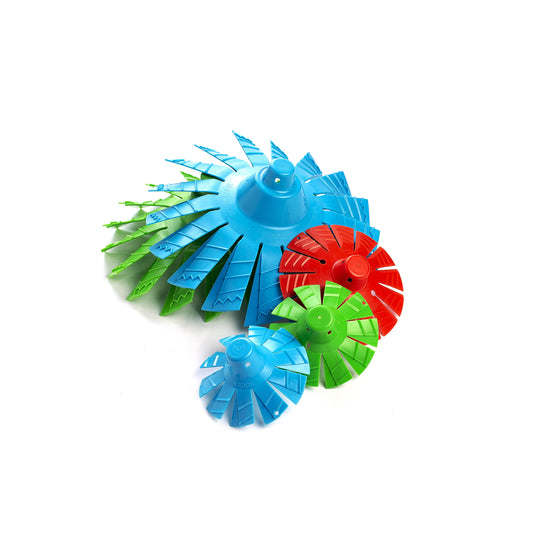

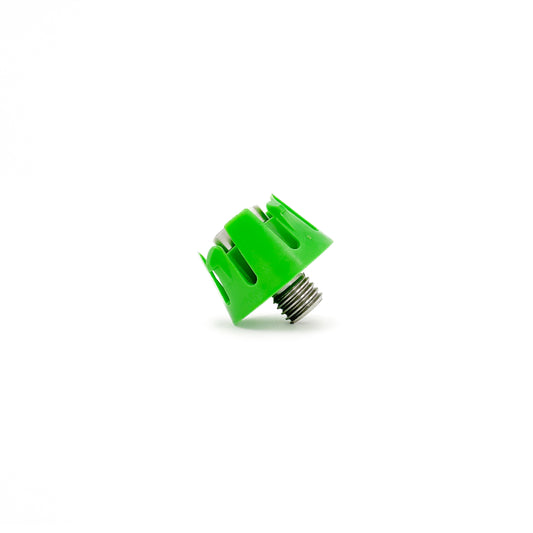

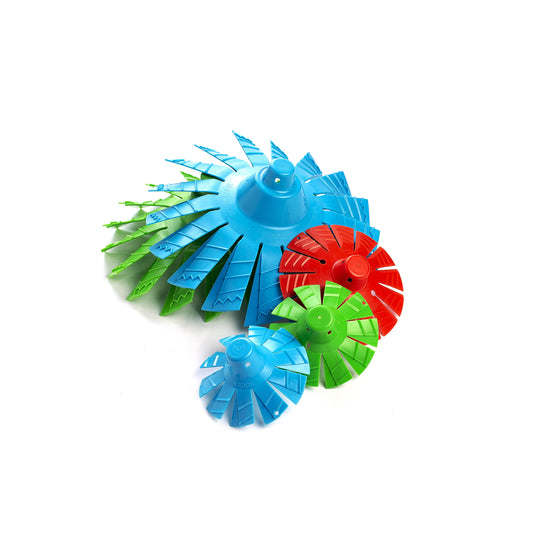

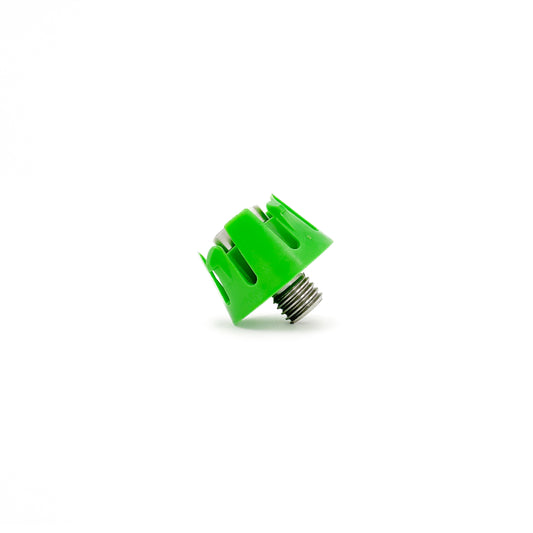

The Solution – BLASTBAG™ Air Decking

Flyrock often comes from poor stemming, confinement issues, or overcharging. MTi proposed using air decking with BLASTBAG™ stemming plugs to improve stemming efficiency.

By creating an air deck inside the blast hole, upward pressure on the stemming was reduced, stemming contamination was avoided, and energy distribution improved. This lowered ejections and improved fragmentation.

MTi’s blasting experts also worked closely with crews, providing engineering support and blast design modifications to ensure safe trials.

Trial Methodology

-

Review current blast design and stemming practices

-

Design test blasts

-

Measure and assess results

Blasts conducted:

-

Blast 1 (POC): 10x10x39 ft, split test (decked vs. non-decked)

-

Blast 2 & 3 (Optimised): 10x10x39 ft, 8.2 ft stemming + 4.9 ft air deck, 5 in hole diameter

Charge weight:

Results

The results were clear:

-

Blast 1: BLASTBAG™ decked holes showed better confinement and less ejection compared to non-decked holes

-

Blast 2: Excellent confinement, major flyrock reduction, and strong fragmentation

-

Blast 3: Consistent improvements and safe performance

With BLASTBAG™ air decking:

-

Flyrock incidents dropped to near zero

-

Charge per hole reduced by 33 lbs (315 → 282 lbs)

-

Safer blasting resumed along the boundary

Adoption

The operator adopted BLASTBAG™ stemming plugs across production blasts. With on-site support from MTi Group and distributor EDM African Resources, operations returned safely and community confidence was restored.

About MTi Group

MTi Group is a global leader in blasting consumables and blasting accessories for mining and quarrying. Our range includes:

-

Blasting plugs, spider plugs, stemming plugs, and blasthole savers

-

Blast hole liners and blast hole covers

-

Blasting signs, explosive placards, and explosive day boxes

-

Blasting machines, 10 cap blasting machines, shock tube initiators, and detonator caps

-

Drillers tape, dip tape, depth gauges, Mitimeasure, and load poles

-

Handheld shooters, heavy duty solar lights, and hole cones

Our solutions — from BLASTBAG™ air decking systems to a complete line of blasting accessories — are engineered to deliver safer, more efficient, and more productive blasting worldwide.